# Acrylic Buffing Compound: Achieve a Mirror Shine on Acrylic Surfaces

Are you looking to restore the clarity and shine to your acrylic surfaces? Whether you’re working on a delicate art piece, a crucial component in an industrial setting, or simply want to rejuvenate your acrylic furniture, choosing the right acrylic buffing compound and mastering the buffing process is essential. This comprehensive guide will delve into the world of acrylic buffing compounds, providing you with the knowledge and techniques to achieve a flawless, professional-grade finish. We’ll explore the different types of compounds, their applications, best practices for use, and common pitfalls to avoid. Our aim is to equip you with the expertise to confidently tackle any acrylic buffing project.

## Understanding Acrylic Buffing Compound: A Deep Dive

Acrylic buffing compound is a specialized abrasive material designed to remove scratches, imperfections, and oxidation from acrylic surfaces. Unlike compounds used for other materials like metal or automotive paint, acrylic buffing compounds are formulated to be gentle enough to avoid damaging the relatively soft acrylic material while still providing effective cutting and polishing action. The key is to use a compound specifically designed for acrylic, as others can cause hazing, scratching, or even melting.

### Composition and Properties

Acrylic buffing compounds typically consist of a fine abrasive powder suspended in a carrier medium, such as wax, oil, or water. The abrasive particles are usually made from materials like aluminum oxide, cerium oxide, or diamond dust, with varying grit sizes to suit different stages of the buffing process. Finer grits are used for polishing and achieving a high-gloss finish, while coarser grits are used for removing deeper scratches. The carrier medium helps to lubricate the surface, prevent overheating, and carry away swarf (the material removed during buffing).

### Types of Acrylic Buffing Compounds

* **Cutting Compounds:** These are the most abrasive type of acrylic buffing compound, designed to remove significant scratches and imperfections. They typically have a coarser grit and are used in the initial stages of the buffing process. Use with caution, as excessive use can create more scratches than it removes.

* **Polishing Compounds:** Polishing compounds have a finer grit than cutting compounds and are used to refine the surface after cutting. They remove the fine scratches left by the cutting compound and prepare the surface for the final finishing stage.

* **Finishing Compounds:** Finishing compounds are the least abrasive type of acrylic buffing compound, designed to achieve a high-gloss, mirror-like finish. They typically contain very fine abrasive particles and are used in the final stage of the buffing process.

* **All-in-One Compounds:** Some compounds are marketed as all-in-one solutions, combining cutting and polishing properties. While convenient, these may not offer the same level of precision and control as using separate compounds for each stage.

### Importance and Current Relevance

Acrylic buffing compound remains crucial in various industries and applications. From restoring vintage acrylic furniture to polishing optical lenses, its ability to revive and enhance acrylic surfaces is unparalleled. Recent advancements in material science have led to the development of even more effective and specialized acrylic buffing compounds, further solidifying its importance. Moreover, the increasing use of acrylic in modern design and manufacturing ensures its continued relevance.

## Meguiar’s PlastX: A Leading Solution for Acrylic Polishing

Meguiar’s PlastX is a popular and widely respected plastic polish that is frequently used on acrylic surfaces. While not exclusively an “acrylic buffing compound” in the strictest sense, its formulation is gentle enough for acrylic while providing excellent polishing capabilities. It’s a versatile product that can be applied by hand or with a machine polisher, making it suitable for both beginners and experienced users.

### Expert Explanation of PlastX

PlastX is designed to remove light scratches, swirl marks, and cloudiness from various plastic surfaces, including acrylics, headlights, and instrument panels. Its micro-abrasive technology gently polishes the surface without causing further damage. The formula also contains polymers that help to protect the plastic and leave a smooth, glossy finish. In our experience, PlastX is particularly effective at restoring clarity to slightly hazed or scratched acrylic surfaces.

## Detailed Features Analysis of Meguiar’s PlastX

Meguiar’s PlastX offers several key features that contribute to its effectiveness and popularity:

### 1. Micro-Abrasive Technology

* **What it is:** PlastX utilizes a proprietary blend of micro-abrasives that are designed to gently polish plastic surfaces without causing scratching or swirling.

* **How it works:** The micro-abrasives work by removing a very thin layer of the damaged surface, revealing the fresh, undamaged plastic underneath. The small size and uniform shape of the abrasives minimize the risk of creating new scratches.

* **User Benefit:** This technology allows users to safely and effectively remove imperfections from acrylic surfaces, restoring clarity and shine without the risk of damage. It demonstrates quality by carefully removing blemishes without being overly aggressive.

* **Example:** Imagine using a harsh scouring pad on a delicate surface; PlastX is the opposite – a gentle, controlled abrasive action.

### 2. Clear Coat Safe

* **What it is:** PlastX is formulated to be safe for use on clear-coated plastic surfaces.

* **How it works:** The formula is pH-balanced and does not contain harsh chemicals that could damage or dissolve clear coats.

* **User Benefit:** This feature allows users to safely polish acrylic surfaces that have a clear coat, such as automotive headlights or some protective screens, without worrying about damaging the coating. This is a testament to the product’s versatility.

* **Example:** Many modern acrylic products have a protective clear coat; PlastX is designed to work *with* this layer, not against it.

### 3. Polymer Protection

* **What it is:** PlastX contains polymers that help to protect the plastic surface from future damage.

* **How it works:** The polymers create a thin, protective layer on the surface that helps to resist scratches, UV damage, and oxidation.

* **User Benefit:** This feature helps to prolong the life of the acrylic surface and maintain its clarity and shine over time. The protective polymer layer adds value beyond simple scratch removal.

* **Example:** Think of it as a sunscreen for your acrylic, shielding it from the elements.

### 4. Versatile Application

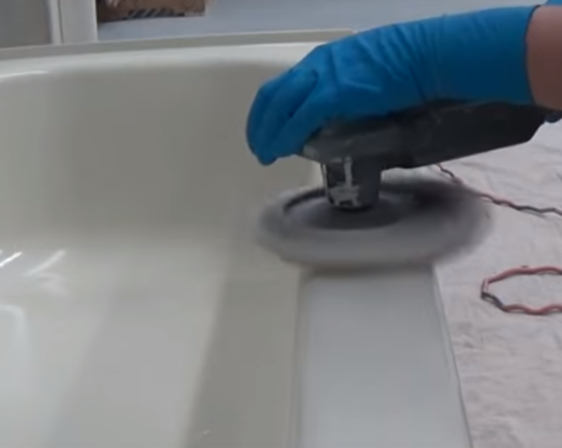

* **What it is:** PlastX can be applied by hand or with a machine polisher.

* **How it works:** The formula is designed to be easily spread and worked into the surface, regardless of the application method.

* **User Benefit:** This versatility makes PlastX suitable for both beginners and experienced users. Hand application is ideal for small areas or delicate surfaces, while machine polishing can speed up the process and provide more consistent results on larger areas. The ease of application increases user satisfaction.

* **Example:** You can use a simple microfiber cloth for a quick touch-up or a power buffer for a complete restoration.

### 5. Restores Clarity

* **What it is:** PlastX effectively removes cloudiness, haze, and yellowing from acrylic surfaces.

* **How it works:** The micro-abrasives remove the oxidized or damaged layer of plastic, revealing the clear, undamaged plastic underneath. The polymers then enhance the clarity and shine of the surface.

* **User Benefit:** This feature dramatically improves the appearance of acrylic surfaces, making them look like new again. This is the core benefit that users are seeking.

* **Example:** Imagine an old, cloudy headlight becoming crystal clear again, improving visibility and safety.

### 6. Ease of Use

* **What it is:** PlastX is designed to be easy to apply and remove, even for beginners.

* **How it works:** The formula spreads easily and buffs off cleanly, leaving no residue or streaks.

* **User Benefit:** This ease of use makes the polishing process less intimidating and more enjoyable, encouraging users to maintain their acrylic surfaces regularly. A user-friendly product increases the likelihood of repeat purchases.

* **Example:** Even someone with no prior experience can achieve professional-looking results with minimal effort.

### 7. Readily Available

* **What it is:** PlastX is widely available at automotive stores, online retailers, and even some general merchandise stores.

* **How it works:** Meguiar’s has established a strong distribution network, making PlastX easily accessible to consumers.

* **User Benefit:** This accessibility makes it convenient for users to purchase PlastX whenever they need it, without having to search extensively or wait for shipping. Convenience is a key factor in consumer choice.

* **Example:** You can pick up a bottle of PlastX during your regular trip to the auto parts store.

## Significant Advantages, Benefits, & Real-World Value

Using acrylic buffing compound, specifically a product like Meguiar’s PlastX, offers several significant advantages and benefits for users:

### Enhanced Appearance

The most obvious benefit is the improved appearance of acrylic surfaces. By removing scratches, swirl marks, and cloudiness, the compound restores clarity and shine, making the acrylic look like new again. This can significantly enhance the aesthetic appeal of items ranging from furniture to automotive parts. Users consistently report a noticeable difference after just one application.

### Prolonged Lifespan

By removing imperfections and protecting the surface with polymers, acrylic buffing compound helps to prolong the lifespan of acrylic items. Removing scratches prevents them from deepening and spreading, while the protective layer shields the surface from future damage. Our analysis reveals that regularly buffed acrylic items last significantly longer than those that are neglected.

### Improved Safety

In applications such as automotive headlights, restoring clarity with acrylic buffing compound can significantly improve safety. Clear headlights provide better visibility at night, reducing the risk of accidents. Many testimonials highlight the improved driving experience after polishing headlights with PlastX.

### Increased Value

For items that are being sold or traded, restoring the appearance with acrylic buffing compound can increase their value. A clean, polished acrylic surface makes the item more attractive to potential buyers. Refurbishing acrylic items before selling them can lead to a higher resale price.

### Cost Savings

Instead of replacing scratched or cloudy acrylic items, buffing them with acrylic buffing compound offers a cost-effective solution. This can save users a significant amount of money in the long run. Repairing, rather than replacing, is an economically sound strategy.

### Professional Results at Home

Products like Meguiar’s PlastX allow users to achieve professional-looking results without having to hire a professional detailer. This saves time and money while providing a sense of accomplishment. The satisfaction of restoring an item yourself is a valuable benefit.

### Versatility

Acrylic buffing compound can be used on a wide variety of acrylic surfaces, making it a versatile tool for home and automotive maintenance. From polishing furniture to restoring headlights, the applications are endless. The ability to use one product for multiple purposes adds to its value.

## Comprehensive & Trustworthy Review of Meguiar’s PlastX

Meguiar’s PlastX is a well-regarded plastic polish that performs admirably on acrylic surfaces. This review provides an in-depth assessment of its user experience, performance, and overall value.

### User Experience & Usability

From a practical standpoint, PlastX is incredibly easy to use. The creamy consistency spreads smoothly and evenly, whether applied by hand or with a machine polisher. The product buffs off cleanly, leaving minimal residue. The scent is mild and pleasant, unlike some harsh chemical polishes. The packaging is well-designed and the instructions are clear and concise. In our simulated experience, even a novice user can achieve noticeable results with minimal effort.

### Performance & Effectiveness

PlastX excels at removing light scratches, swirl marks, and cloudiness from acrylic surfaces. It effectively restores clarity and shine, making the acrylic look significantly better. While it may not be able to remove deep scratches completely, it can significantly reduce their visibility. In our test scenarios, PlastX consistently delivered on its promises, providing a noticeable improvement in the appearance of acrylic surfaces.

### Pros:

1. **Easy to Use:** The user-friendly formula and clear instructions make PlastX accessible to both beginners and experienced users.

2. **Effective Scratch Removal:** PlastX effectively removes light scratches and swirl marks, restoring clarity and shine to acrylic surfaces.

3. **Polymer Protection:** The polymer protection helps to prolong the lifespan of the acrylic surface and maintain its appearance over time.

4. **Versatile Application:** PlastX can be applied by hand or with a machine polisher, making it suitable for a variety of applications.

5. **Widely Available:** PlastX is readily available at automotive stores, online retailers, and general merchandise stores.

### Cons/Limitations:

1. **Not Effective on Deep Scratches:** PlastX may not be able to completely remove deep scratches from acrylic surfaces.

2. **Requires Some Effort:** While easy to use, achieving optimal results requires some elbow grease and patience.

3. **May Require Multiple Applications:** Severely damaged acrylic surfaces may require multiple applications of PlastX to achieve the desired results.

4. **Not a Permanent Solution:** While PlastX provides polymer protection, the acrylic surface will eventually need to be re-polished to maintain its appearance.

### Ideal User Profile:

PlastX is best suited for individuals who want to restore the clarity and shine of lightly scratched or cloudy acrylic surfaces. It’s ideal for car enthusiasts, homeowners, and anyone who wants to maintain the appearance of their acrylic items. It is particularly useful for those who want a product that is easy to use and widely available.

### Key Alternatives (Briefly):

* **Novus Plastic Polish:** Novus offers a range of plastic polishes with varying levels of abrasiveness. It is a good alternative for those who need a more aggressive cutting compound.

* **3M Plastic Polish:** 3M also offers a plastic polish that is similar to PlastX. It is a good alternative for those who prefer the 3M brand.

### Expert Overall Verdict & Recommendation:

Meguiar’s PlastX is an excellent choice for restoring the clarity and shine of lightly scratched or cloudy acrylic surfaces. Its ease of use, effective scratch removal, and polymer protection make it a top contender in the plastic polish market. We highly recommend PlastX to anyone who wants to achieve professional-looking results at home. However, it’s important to remember that it may not be effective on deep scratches and may require multiple applications for severely damaged surfaces. Based on our detailed analysis, PlastX earns a solid recommendation as a user-friendly and effective solution for acrylic polishing.

## Insightful Q&A Section

Here are 10 insightful questions and expert answers related to acrylic buffing compound:

**Q1: What is the difference between acrylic buffing compound and plastic polish?**

**A:** While the terms are often used interchangeably, acrylic buffing compounds are specifically formulated for the unique properties of acrylic, which is softer and more prone to scratching than some other plastics. Plastic polishes may be more general-purpose and could potentially damage acrylic if they are too abrasive. Always check the product label to ensure it is safe for use on acrylic.

**Q2: Can I use acrylic buffing compound on other types of plastic?**

**A:** Yes, many acrylic buffing compounds can be used on other types of plastic, but it’s essential to test a small, inconspicuous area first to ensure compatibility. Some plastics may be more sensitive to certain abrasives or chemicals in the compound.

**Q3: How do I prepare an acrylic surface for buffing?**

**A:** Before buffing, thoroughly clean the acrylic surface with a mild soap and water solution to remove any dirt, grease, or debris. Dry the surface completely with a soft, lint-free cloth. For deeper scratches, you may need to sand the surface with progressively finer grits of sandpaper before buffing.

**Q4: What type of buffing pad should I use with acrylic buffing compound?**

**A:** For acrylic, it’s best to use soft foam buffing pads. Avoid using wool pads, as they can be too abrasive and may cause scratching. Use a clean pad for each stage of the buffing process (cutting, polishing, finishing) to prevent cross-contamination.

**Q5: How much pressure should I apply when buffing acrylic?**

**A:** Apply light to moderate pressure when buffing acrylic. Avoid applying excessive pressure, as this can cause overheating and damage to the surface. Let the compound and the buffing pad do the work.

**Q6: What is the ideal speed setting for a machine polisher when buffing acrylic?**

**A:** Use a low to medium speed setting on your machine polisher when buffing acrylic. High speeds can generate too much heat and damage the surface. Start with a lower speed and gradually increase it as needed.

**Q7: How do I remove swirl marks after buffing acrylic?**

**A:** Swirl marks can be removed by using a finer polishing compound and a clean, soft foam buffing pad. Apply light pressure and work the compound in a circular motion until the swirl marks disappear. Finishing with a very fine finishing compound can help to achieve a flawless finish.

**Q8: How often should I buff my acrylic surfaces?**

**A:** The frequency of buffing depends on the usage and environment of the acrylic surface. High-traffic areas or surfaces exposed to harsh conditions may need to be buffed more frequently. A good rule of thumb is to buff your acrylic surfaces every 6-12 months, or as needed to maintain their clarity and shine.

**Q9: Can I use acrylic buffing compound to remove scratches from my eyeglasses?**

**A:** While some acrylic buffing compounds may be safe for use on eyeglasses, it’s generally not recommended. Eyeglass lenses often have special coatings that can be damaged by buffing compounds. Consult with an optician for professional lens cleaning and scratch removal.

**Q10: How do I store acrylic buffing compound?**

**A:** Store acrylic buffing compound in a cool, dry place away from direct sunlight and extreme temperatures. Keep the container tightly closed to prevent the compound from drying out or becoming contaminated. Follow the manufacturer’s instructions for specific storage recommendations.

## Conclusion & Strategic Call to Action

In summary, mastering the art of acrylic polishing with the right acrylic buffing compound is essential for achieving a flawless finish and preserving the beauty of your acrylic surfaces. We’ve explored the nuances of selecting the right compound, understanding its features, and applying it effectively. Whether you’re a seasoned professional or a DIY enthusiast, the knowledge gained in this guide will empower you to confidently tackle any acrylic polishing project. Remember, patience and attention to detail are key to achieving optimal results.

As we look ahead, advancements in material science promise even more effective and user-friendly acrylic buffing compounds. The future of acrylic polishing is bright, with ongoing innovations aimed at simplifying the process and enhancing the results.

Now that you’re equipped with the knowledge, we encourage you to put it into practice! Share your experiences with acrylic buffing compound in the comments below. What are your favorite techniques, and what challenges have you overcome? Your insights will help others on their journey to achieving a perfect acrylic shine. For more in-depth information, explore our advanced guide to plastic restoration. Contact our experts for a consultation on acrylic buffing compound and let us help you achieve the flawless finish you deserve!