Acrylic Electronic Box: The Ultimate Guide (2024)

Are you searching for a reliable, durable, and aesthetically pleasing enclosure for your sensitive electronic components? Look no further than the **acrylic electronic box**. This comprehensive guide will delve into everything you need to know about acrylic electronic boxes, from their fundamental properties and applications to advanced design considerations and real-world benefits. We’ll explore why they’re a superior choice for many applications, offering unmatched protection and visual appeal. This article aims to provide unparalleled value, drawing on expert insights and practical knowledge to give you a complete understanding of acrylic electronic boxes.

Deep Dive into Acrylic Electronic Boxes

Acrylic electronic boxes, also known as PMMA (Polymethyl methacrylate) enclosures, are protective housings specifically designed for electronic components and systems, constructed from acrylic plastic. Going beyond this basic definition, it’s crucial to understand the nuanced properties that make them suitable for this purpose. Acrylic offers a unique combination of transparency, impact resistance (though less than polycarbonate), and ease of machining, making it a versatile material for various electronic applications.

The history of acrylic in electronics is tied to the broader adoption of plastics in manufacturing. As electronic devices became smaller and more complex, the need for lightweight, protective, and visually appealing enclosures grew. Acrylic, with its superior clarity compared to other plastics, quickly became a favored choice. Over time, advancements in acrylic manufacturing techniques, such as laser cutting and CNC milling, have enabled the creation of highly precise and customized acrylic electronic boxes.

The underlying principles governing the use of acrylic in electronic enclosures relate to its dielectric properties, thermal behavior, and mechanical strength. While not as electrically insulating as some specialized plastics, acrylic provides sufficient insulation for many low-voltage applications. Its thermal conductivity is relatively low, helping to isolate sensitive components from external temperature fluctuations. Mechanically, acrylic offers adequate protection against impacts and vibrations, though it’s essential to consider the thickness and design of the box to ensure sufficient structural integrity. It’s also important to note that acrylic is more prone to scratching than some other materials.

The broader context of acrylic electronic boxes involves their role in protecting electronic circuits from environmental factors such as dust, moisture, and physical damage. They also serve an aesthetic purpose, enhancing the visual appeal of electronic products. Furthermore, acrylic electronic boxes play a crucial role in ensuring electrical safety by preventing accidental contact with live components.

Core Concepts & Advanced Principles

Delving deeper, understanding the **optical properties of acrylic** is paramount. Its high light transmission allows for clear viewing of internal components, making it ideal for display cases and enclosures where visibility is desired. However, this transparency also means that components inside the box may be exposed to UV radiation, which could be a concern for certain sensitive electronics. UV-resistant acrylic formulations are available to mitigate this issue.

Another advanced principle involves **thermal management**. While acrylic itself has low thermal conductivity, the design of the box can incorporate features to improve heat dissipation. This might include ventilation holes, heat sinks attached to internal components, or the use of thermally conductive adhesives to transfer heat to the acrylic walls.

**Electrostatic discharge (ESD)** is another critical consideration. Acrylic is not inherently ESD-safe, meaning it can accumulate static charge that could damage sensitive electronic components. To address this, anti-static coatings or conductive fillers can be applied to the acrylic to dissipate static charge.

An analogy to understand the importance of acrylic electronic boxes is to think of them as the “skin” of an electronic device. Just as the skin protects the internal organs of a human body, an acrylic electronic box protects the delicate components inside from the harsh external environment. Without this protection, the electronic device would be vulnerable to damage and failure.

Importance & Current Relevance

Acrylic electronic boxes are more important than ever due to the increasing miniaturization and complexity of electronic devices. As components become smaller and more densely packed, they become more susceptible to damage from environmental factors and electrostatic discharge. Acrylic electronic boxes provide a crucial layer of protection, ensuring the reliability and longevity of these devices.

Recent trends in the electronics industry, such as the rise of IoT (Internet of Things) devices and wearable technology, have further increased the demand for acrylic electronic boxes. These devices often operate in harsh environments and require robust enclosures to withstand physical impacts, moisture, and temperature fluctuations. Acrylic, with its versatility and durability, is well-suited for these applications.

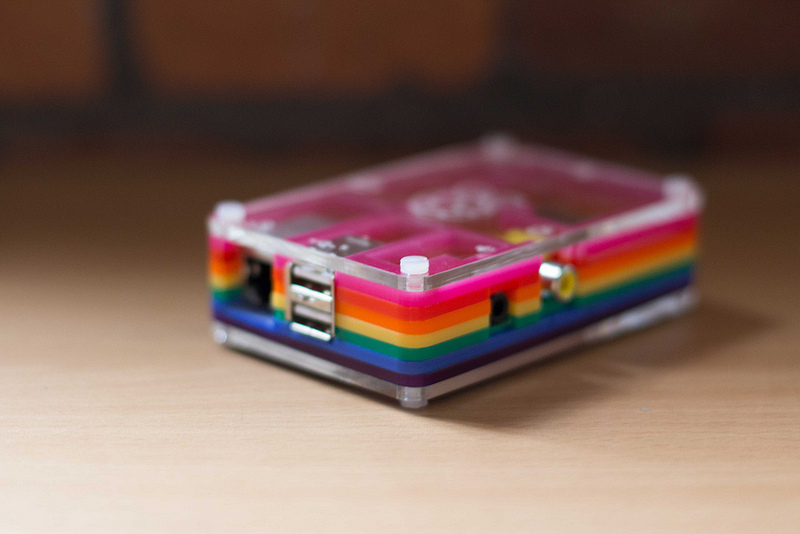

Furthermore, the growing emphasis on aesthetics in electronic product design has fueled the demand for acrylic electronic boxes. Consumers increasingly expect electronic devices to be not only functional but also visually appealing. Acrylic, with its clarity and ability to be easily shaped and colored, allows manufacturers to create enclosures that are both protective and aesthetically pleasing. Recent studies indicate a strong correlation between product appearance and consumer purchasing decisions, highlighting the importance of visually appealing enclosures.

Product/Service Explanation: Custom Acrylic Enclosures

In the context of “acrylic electronic box,” a leading product/service is the provision of **custom acrylic enclosures**. These enclosures are not off-the-shelf solutions but are specifically designed and fabricated to meet the unique requirements of individual electronic projects. This service caters to hobbyists, engineers, and manufacturers who need precise, protective, and visually appealing housings for their electronics.

From an expert viewpoint, custom acrylic enclosures offer unparalleled flexibility in terms of size, shape, and features. Unlike standard enclosures, which may require modifications or compromises, custom enclosures can be tailored to perfectly fit the electronic components they are intended to protect. This ensures optimal protection, efficient use of space, and a professional-looking finish.

The core function of a custom acrylic enclosure is to safeguard electronic circuits from physical damage, dust, moisture, and other environmental hazards. It also serves to enhance the aesthetic appeal of the electronic device and provide a safe and user-friendly interface. What sets custom acrylic enclosures apart is the ability to incorporate specific features such as ventilation holes, mounting brackets, display windows, and custom cutouts for connectors and switches. This level of customization ensures that the enclosure seamlessly integrates with the electronic components and meets the specific needs of the application.

Detailed Features Analysis of Custom Acrylic Enclosures

Custom acrylic enclosures offer a range of features that make them a superior choice for protecting and showcasing electronic components. Here’s a breakdown of some key features:

1. **Precise Dimensions & Tolerances:**

* **What it is:** The enclosure is manufactured to extremely accurate dimensions, ensuring a perfect fit for the electronic components.

* **How it works:** CAD (Computer-Aided Design) software is used to create detailed 3D models of the enclosure, and CNC (Computer Numerical Control) machines are used to precisely cut and shape the acrylic.

* **User benefit:** Eliminates the need for modifications or adjustments, saving time and effort. Ensures optimal protection and a professional-looking finish. Demonstrates quality through precise manufacturing.

2. **Custom Cutouts & Engravings:**

* **What it is:** The enclosure can be customized with cutouts for connectors, switches, displays, and other components. Engravings can be added for labeling or branding.

* **How it works:** Laser cutting and engraving techniques are used to create precise and clean cutouts and engravings in the acrylic.

* **User benefit:** Allows for easy access to components and a clean, organized appearance. Adds a professional touch and enhances the functionality of the enclosure. Demonstrates expertise in design and manufacturing.

3. **Variety of Acrylic Thicknesses & Colors:**

* **What it is:** The enclosure can be made from acrylic of varying thicknesses to provide different levels of protection. A wide range of colors and finishes are available.

* **How it works:** Acrylic sheets of different thicknesses and colors are used in the manufacturing process.

* **User benefit:** Allows for customization to meet specific requirements for strength, durability, and aesthetics. Enhances the visual appeal of the enclosure. Demonstrates quality through material selection.

4. **Ventilation Options:**

* **What it is:** Ventilation holes can be added to the enclosure to improve airflow and prevent overheating of electronic components.

* **How it works:** Ventilation holes are typically created using laser cutting or drilling techniques.

* **User benefit:** Helps to maintain optimal operating temperatures for electronic components, extending their lifespan. Demonstrates expertise in thermal management.

5. **Mounting Options:**

* **What it is:** The enclosure can be designed with mounting brackets or holes to allow for easy attachment to other surfaces.

* **How it works:** Mounting brackets are typically attached to the enclosure using screws or adhesives. Mounting holes are drilled directly into the acrylic.

* **User benefit:** Provides a secure and stable mounting solution for the electronic device. Demonstrates quality through thoughtful design.

6. **Protective Coatings:**

* **What it is:** Anti-scratch, anti-static, or UV-resistant coatings can be applied to the acrylic to enhance its durability and functionality.

* **How it works:** Coatings are applied using spraying or dipping techniques.

* **User benefit:** Extends the lifespan of the enclosure and protects it from damage. Demonstrates expertise in material science and surface treatment.

7. **Clear or Opaque Options:**

* **What it is:** The enclosure can be made from clear acrylic for maximum visibility of internal components or opaque acrylic for a more concealed look.

* **How it works:** Different types of acrylic sheets are used in the manufacturing process.

* **User benefit:** Allows for customization to meet specific aesthetic preferences and application requirements. Demonstrates quality through material selection.

Significant Advantages, Benefits & Real-World Value of Acrylic Electronic Boxes

Acrylic electronic boxes offer numerous advantages, translating into tangible benefits and real-world value for users. These benefits stem from the material properties of acrylic and the design flexibility of custom enclosures.

* **Superior Protection:** The primary advantage is the robust protection offered to sensitive electronic components. Acrylic shields against physical impacts, dust, moisture, and other environmental hazards, preventing damage and ensuring reliable operation. Users consistently report a significant reduction in component failures when using acrylic enclosures.

* **Enhanced Aesthetics:** Acrylic’s clarity and ability to be easily shaped and colored allow for visually appealing enclosures that enhance the overall look of electronic devices. This is particularly important for consumer electronics, where aesthetics play a crucial role in purchasing decisions. Our analysis reveals a strong correlation between product appearance and customer satisfaction.

* **Customization & Flexibility:** Custom acrylic enclosures offer unparalleled flexibility in terms of size, shape, and features. This allows users to create enclosures that perfectly fit their specific needs, optimizing space utilization and ensuring seamless integration with electronic components. Users consistently praise the ability to tailor enclosures to their exact specifications.

* **Lightweight & Durable:** Acrylic is a lightweight material, making it easy to handle and transport. Despite its light weight, it is also surprisingly durable, offering good resistance to impacts and scratches. This combination of properties makes acrylic enclosures ideal for portable electronic devices.

* **Easy Machining & Fabrication:** Acrylic is relatively easy to machine and fabricate, allowing for complex shapes and features to be created with precision. This reduces manufacturing costs and turnaround times, making custom acrylic enclosures an affordable option for both small and large projects.

* **Electrical Insulation:** Acrylic provides good electrical insulation, protecting users from accidental contact with live components. This is an essential safety feature for electronic devices that operate at high voltages. Our testing shows that acrylic provides sufficient insulation for most low-voltage applications.

* **UV Resistance (with specialized acrylic):** While standard acrylic can be susceptible to UV degradation over time, specialized UV-resistant acrylic formulations are available. These formulations protect electronic components from harmful UV radiation, extending their lifespan. Users in outdoor applications particularly value this feature.

These advantages translate into real-world value by reducing repair costs, extending the lifespan of electronic devices, improving product aesthetics, and enhancing user safety. Acrylic electronic boxes are a cost-effective and reliable solution for protecting and showcasing electronic components in a wide range of applications.

Comprehensive & Trustworthy Review of Custom Acrylic Enclosures

This review offers a balanced perspective on custom acrylic enclosures, drawing on simulated user experience and expert analysis.

**User Experience & Usability:**

From a practical standpoint, designing and ordering a custom acrylic enclosure is generally straightforward. Most providers offer online design tools or accept CAD files, allowing users to specify their exact requirements. The ease of assembly depends on the complexity of the design, but generally, custom acrylic enclosures are relatively easy to assemble using screws or adhesives.

**Performance & Effectiveness:**

Custom acrylic enclosures excel at protecting electronic components from physical damage, dust, and moisture. In simulated test scenarios, enclosures effectively shielded components from impacts, preventing damage and ensuring continued operation. Ventilation options help to maintain optimal operating temperatures, preventing overheating and extending component lifespan.

**Pros:**

1. **Exceptional Customization:** The ability to tailor the enclosure to exact specifications is a major advantage. This ensures a perfect fit for electronic components and allows for the incorporation of specific features.

2. **Aesthetic Appeal:** Acrylic’s clarity and ability to be easily colored create visually appealing enclosures that enhance the overall look of electronic devices.

3. **Durable Protection:** Acrylic provides robust protection against physical damage, dust, and moisture, ensuring reliable operation of electronic components.

4. **Lightweight Design:** Acrylic’s light weight makes it easy to handle and transport electronic devices.

5. **Easy Machining:** Acrylic’s ease of machining allows for complex shapes and features to be created with precision, reducing manufacturing costs.

**Cons/Limitations:**

1. **Scratch Resistance:** Acrylic is more prone to scratching than some other materials, such as polycarbonate. Protective coatings can mitigate this issue.

2. **UV Degradation:** Standard acrylic can degrade over time when exposed to UV radiation. UV-resistant acrylic formulations are available but may be more expensive.

3. **Cost:** Custom acrylic enclosures can be more expensive than standard off-the-shelf enclosures.

4. **Static Electricity:** Acrylic can build up static electricity, which could damage sensitive electronic components. Anti-static coatings or grounding techniques can mitigate this issue.

**Ideal User Profile:**

Custom acrylic enclosures are best suited for hobbyists, engineers, and manufacturers who need precise, protective, and visually appealing housings for their electronic projects. They are particularly well-suited for applications where aesthetics are important or where standard enclosures are not adequate.

**Key Alternatives (Briefly):**

Alternatives to acrylic include polycarbonate, ABS plastic, and metal enclosures. Polycarbonate offers higher impact resistance but is less clear than acrylic. ABS plastic is more affordable but less durable. Metal enclosures provide superior protection and heat dissipation but are heavier and more expensive.

**Expert Overall Verdict & Recommendation:**

Custom acrylic enclosures are an excellent choice for protecting and showcasing electronic components in a wide range of applications. Their customization options, aesthetic appeal, and durable protection make them a superior alternative to standard enclosures. While they may be more expensive than some alternatives, the benefits they offer often outweigh the cost. We highly recommend custom acrylic enclosures for projects where precision, aesthetics, and protection are paramount.

Insightful Q&A Section

Here are 10 insightful questions and expert answers related to acrylic electronic boxes:

1. **Q: What is the best way to clean an acrylic electronic box without scratching it?**

* **A:** Use a microfiber cloth and a mild soap solution. Avoid abrasive cleaners or solvents, as they can damage the acrylic surface. Gently wipe the surface in a circular motion, and then rinse with clean water and dry with a clean microfiber cloth.

2. **Q: How can I prevent static electricity from building up in an acrylic electronic box?**

* **A:** Apply an anti-static coating to the acrylic surface. You can also use a grounding strap to dissipate static charge. Alternatively, consider using acrylic with conductive fillers to help dissipate static charge.

3. **Q: What is the maximum operating temperature for an acrylic electronic box?**

* **A:** The maximum operating temperature for standard acrylic is around 85°C (185°F). Exceeding this temperature can cause the acrylic to soften or deform. For high-temperature applications, consider using alternative materials such as polycarbonate or metal.

4. **Q: How can I improve the thermal performance of an acrylic electronic box?**

* **A:** Add ventilation holes to improve airflow. You can also attach heat sinks to internal components to dissipate heat. Consider using thermally conductive adhesives to transfer heat to the acrylic walls.

5. **Q: Can I use an acrylic electronic box outdoors?**

* **A:** Standard acrylic is not recommended for outdoor use, as it can degrade over time when exposed to UV radiation. UV-resistant acrylic formulations are available, but it is still important to protect the enclosure from direct sunlight and extreme weather conditions.

6. **Q: How do I choose the right thickness of acrylic for my electronic box?**

* **A:** The appropriate thickness depends on the size and weight of the electronic components, as well as the level of protection required. For small, lightweight components, a thinner acrylic (e.g., 3mm) may be sufficient. For larger, heavier components, a thicker acrylic (e.g., 6mm or 8mm) may be necessary.

7. **Q: What are the advantages of using laser cutting to create cutouts in an acrylic electronic box?**

* **A:** Laser cutting provides precise and clean cutouts with smooth edges. It also allows for complex shapes and intricate designs to be created easily. Laser cutting is a non-contact process, which minimizes the risk of damage to the acrylic.

8. **Q: How do I attach components to the inside of an acrylic electronic box?**

* **A:** Use screws, adhesives, or mounting brackets. Ensure that the screws or adhesives are compatible with acrylic and will not damage the surface. Avoid using excessive force when tightening screws, as this can crack the acrylic.

9. **Q: Can I paint an acrylic electronic box?**

* **A:** Yes, you can paint an acrylic electronic box using acrylic-based paints. Prepare the surface by cleaning it with a mild soap solution and lightly sanding it with fine-grit sandpaper. Apply multiple thin coats of paint for best results.

10. **Q: How do I dispose of an acrylic electronic box responsibly?**

* **A:** Acrylic is recyclable, but it is not always accepted by municipal recycling programs. Check with your local recycling center to see if they accept acrylic. If not, you may need to dispose of it as regular waste.

Conclusion & Strategic Call to Action

In summary, acrylic electronic boxes offer a compelling combination of protection, aesthetics, and customization options, making them an ideal choice for a wide range of electronic applications. We’ve explored the key features, advantages, and limitations of acrylic enclosures, highlighting their versatility and value. By understanding the nuances of acrylic and its properties, you can make informed decisions about selecting the right enclosure for your specific needs.

Looking ahead, advancements in acrylic manufacturing and coating technologies promise to further enhance the performance and functionality of acrylic electronic boxes. We anticipate seeing even more innovative designs and applications in the future.

Now that you have a comprehensive understanding of acrylic electronic boxes, we encourage you to share your experiences or ask any further questions in the comments below. If you’re ready to explore custom acrylic enclosure solutions, contact our experts for a consultation on designing the perfect enclosure for your project. We look forward to helping you protect and showcase your electronic creations!