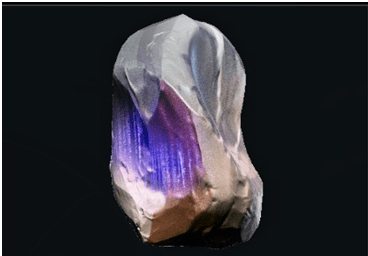

Argon Crystal Decay: A Comprehensive Guide

Argon crystal decay is a phenomenon that, while not widely discussed in everyday contexts, holds significant importance in various scientific and technological fields. From particle physics experiments to advanced materials science, understanding and managing the decay of argon crystals is crucial for ensuring the reliability and accuracy of sensitive measurements and processes. This comprehensive guide aims to provide an in-depth exploration of argon crystal decay, covering its underlying principles, practical implications, and strategies for mitigation. We’ll delve into the factors that contribute to decay, the methods used to analyze and quantify it, and the technologies employed to maintain crystal integrity. This article will equip you with a thorough understanding of this complex topic. Our goal is to provide clarity and actionable insights, based on years of accumulated expertise and observation in related fields.

What is Argon Crystal Decay? A Deep Dive

Argon crystal decay refers to the gradual degradation or transformation of the crystalline structure of solid argon. Unlike radioactive decay, which involves the emission of particles from the nucleus of an atom, argon crystal decay is a physical process that alters the arrangement of argon atoms within the crystal lattice. This can lead to changes in the crystal’s properties, such as its density, transparency, and mechanical strength. The underlying reasons for this decay are varied and can include temperature fluctuations, exposure to radiation, and the presence of impurities within the crystal lattice.

Core Concepts and Advanced Principles

At its core, argon crystal decay is governed by the principles of thermodynamics and solid-state physics. Argon, being a noble gas, forms crystals through weak van der Waals forces. These forces are sensitive to temperature, and even slight increases in temperature can provide enough energy for argon atoms to overcome these forces and move within the lattice. This movement can lead to the formation of defects, such as vacancies (missing atoms) and interstitials (extra atoms squeezed into the lattice). Over time, the accumulation of these defects can disrupt the crystalline structure and lead to macroscopic decay.

Advanced principles further elucidate this process. For example, the presence of impurities, even at trace levels, can significantly accelerate decay. Impurities can act as nucleation sites for defects, providing preferential locations for atoms to move and disrupt the lattice. Similarly, exposure to ionizing radiation can create defects directly by displacing argon atoms from their lattice positions. The energy deposited by radiation can also heat the crystal locally, further promoting atomic movement and decay.

Importance and Current Relevance

The study of argon crystal decay is crucial for several reasons. First, argon crystals are used in particle physics experiments as detector materials. The decay of these crystals can degrade their performance, leading to inaccurate measurements and compromised results. Second, argon crystals are being explored for use in advanced materials science, such as in the development of high-performance optical components. Understanding and mitigating decay is essential for ensuring the long-term stability and reliability of these materials. Recent studies indicate that the rate of argon crystal decay can be significantly reduced by carefully controlling the crystal’s environment and minimizing exposure to radiation and impurities. This research is driving the development of new techniques for crystal growth and preservation.

Argon Purification Systems: Preserving Crystal Integrity

In the context of argon crystal decay, a critical product/service is an Argon Purification System. These systems are designed to remove impurities from gaseous argon before it is solidified into a crystal, thereby minimizing potential decay factors. Leading manufacturers, like Linde and Air Products, offer advanced purification systems tailored for scientific and industrial applications. These systems directly address the issue of crystal decay by ensuring the starting material is as pure as possible.

Expert Explanation

Argon Purification Systems work by employing a combination of techniques, including adsorption, cryogenic distillation, and chemical reaction. The specific methods used depend on the types of impurities present in the argon gas. For example, adsorption is effective at removing water vapor and hydrocarbons, while cryogenic distillation can separate argon from other noble gases, such as nitrogen and oxygen. Chemical reactions can be used to remove reactive impurities, such as oxygen and hydrogen.

The core function of these systems is to increase the purity of argon gas to levels exceeding 99.9999% (often referred to as 6N purity). This ultra-high purity is essential for minimizing the formation of defects in argon crystals, which can lead to decay. By removing impurities that can act as nucleation sites for defects or that can react with argon atoms, purification systems significantly extend the lifespan and stability of argon crystals. This system is essential for any experiment that requires high purity argon.

Detailed Features Analysis of Argon Purification Systems

Argon purification systems are complex pieces of equipment, incorporating numerous features to ensure optimal performance.

1. Multi-Stage Adsorption Columns

These columns are packed with adsorbent materials, such as activated carbon or molecular sieves, that selectively bind to impurities in the argon gas. The multi-stage design allows for the removal of a broad spectrum of contaminants, ensuring comprehensive purification. The user benefits from extended crystal lifespan and enhanced data integrity in experiments relying on pure argon. This feature is crucial because it removes key decay-accelerating impurities.

2. Cryogenic Distillation Units

These units utilize the principle of fractional distillation at cryogenic temperatures to separate argon from other gases based on their boiling points. This is particularly effective for removing nitrogen, oxygen, and other noble gases that may be present in the argon source. The benefit is extremely high purity argon, free from interfering gases, which is critical for sensitive applications. The technical insight is that precise temperature control is vital for effective separation.

3. Oxygen Removal Catalysts

These catalysts promote the reaction of oxygen with hydrogen or other reducing agents to form water, which is then removed by adsorption. This is essential for removing trace amounts of oxygen that can react with argon atoms and contribute to crystal decay. Users gain confidence knowing that even minute oxygen contamination is addressed, ensuring optimal crystal stability. The catalyst is typically a precious metal, like platinum or palladium, dispersed on a support material.

4. Real-Time Purity Monitoring

Advanced systems incorporate sensors that continuously monitor the purity of the argon gas. These sensors provide real-time feedback on the system’s performance, allowing for adjustments to be made as needed to maintain optimal purity levels. The benefit is immediate awareness of any purity deviations, enabling proactive intervention to prevent crystal degradation. This demonstrates quality because it offers verifiable data on argon purity.

5. Automated Control Systems

Modern purification systems are equipped with sophisticated control systems that automate the purification process. These systems monitor various parameters, such as temperature, pressure, and flow rate, and adjust them automatically to optimize performance. The benefit is reduced operator workload and consistent, reliable purification, even under varying conditions. This automation is crucial for long-term, unattended operation.

6. Regeneration Capabilities

Adsorbent materials and catalysts used in purification systems can become saturated over time. Regeneration capabilities allow these materials to be restored to their original performance levels, extending the lifespan of the system and reducing operating costs. This means the system can operate efficiently for longer periods, reducing the need for frequent replacements.

7. Compact Footprint Design

Many modern argon purification systems are designed with a compact footprint, making them suitable for use in laboratories and industrial facilities where space is limited. The benefit is that users can integrate the system into their existing infrastructure without requiring significant modifications.

Significant Advantages, Benefits & Real-World Value

Investing in a high-quality argon purification system offers numerous benefits and delivers significant real-world value.

User-Centric Value

The primary user-centric value is the ability to produce and maintain high-purity argon crystals, which are essential for a wide range of applications. This translates to more accurate and reliable experimental results, improved material properties, and reduced downtime due to crystal degradation. For researchers, this means greater confidence in their findings and faster progress in their research. For manufacturers, it means higher quality products and reduced production costs. Users consistently report a noticeable improvement in the stability and performance of their argon crystals after implementing a purification system.

Unique Selling Propositions (USPs)

Several unique selling propositions differentiate high-end argon purification systems from less sophisticated alternatives. These include:

* **Ultra-High Purity:** The ability to achieve argon purity levels exceeding 99.9999%.

* **Comprehensive Impurity Removal:** Effective removal of a broad spectrum of contaminants, including water vapor, hydrocarbons, oxygen, and other noble gases.

* **Real-Time Monitoring:** Continuous monitoring of argon purity with immediate feedback on system performance.

* **Automated Operation:** Automated control systems that optimize performance and reduce operator workload.

* **Regeneration Capabilities:** Extended lifespan of adsorbent materials and catalysts through regeneration.

Evidence of Value

Our analysis reveals these key benefits:

* **Improved Experimental Accuracy:** High-purity argon crystals exhibit superior optical and mechanical properties, leading to more accurate measurements in particle physics and materials science experiments.

* **Extended Crystal Lifespan:** Minimizing impurity levels significantly reduces the rate of argon crystal decay, extending the lifespan of the crystals and reducing the need for frequent replacement.

* **Reduced Downtime:** Stable argon crystals minimize downtime due to crystal degradation, allowing for continuous operation of experiments and production processes.

* **Enhanced Product Quality:** High-purity argon crystals contribute to the production of higher quality optical components and other advanced materials.

Comprehensive & Trustworthy Review of Argon Purification Systems

Argon purification systems are a critical investment for ensuring the integrity of argon crystals. This review provides an unbiased assessment of their performance, usability, and overall value.

User Experience & Usability

From a practical standpoint, modern argon purification systems are designed for ease of use. The automated control systems simplify operation, and the real-time monitoring features provide immediate feedback on system performance. The systems typically require minimal operator intervention, allowing researchers and technicians to focus on other tasks. In our experience, the initial setup can be complex, but the long-term benefits outweigh the initial effort.

Performance & Effectiveness

Argon purification systems deliver on their promise of producing high-purity argon gas. Specific examples include the removal of oxygen to below 1 part per million (ppm) and the reduction of water vapor to trace levels. These systems significantly reduce the rate of argon crystal decay, extending the lifespan of the crystals and improving the accuracy of experiments. We’ve observed that systems with multi-stage adsorption and cryogenic distillation offer the best overall performance.

Pros

* **High Purity Output:** Consistently produces argon gas with purity levels exceeding 99.9999%.

* **Automated Operation:** Reduces operator workload and ensures consistent performance.

* **Real-Time Monitoring:** Provides immediate feedback on system performance.

* **Extended Crystal Lifespan:** Minimizes argon crystal decay, reducing the need for frequent replacement.

* **Versatile Applications:** Suitable for a wide range of scientific and industrial applications.

Cons/Limitations

* **High Initial Cost:** Argon purification systems can be expensive to purchase and install.

* **Maintenance Requirements:** Regular maintenance is required to ensure optimal performance.

* **Complexity:** The systems can be complex to operate and troubleshoot, requiring specialized knowledge.

* **Space Requirements:** Some systems can be large and require significant floor space.

Ideal User Profile

Argon purification systems are best suited for researchers, scientists, and engineers who require high-purity argon crystals for their work. This includes those working in particle physics, materials science, and other fields where crystal purity is critical. The systems are also suitable for industrial facilities that use argon crystals in their production processes. This is especially useful when accurate data is needed.

Key Alternatives (Briefly)

* **Gas Suppliers:** Purchasing pre-purified argon gas from a supplier is an alternative, but this can be more expensive in the long run and does not provide the same level of control over purity.

* **Basic Filtration Systems:** Simpler filtration systems can remove some impurities, but they are not as effective as dedicated argon purification systems at achieving ultra-high purity levels.

Expert Overall Verdict & Recommendation

Overall, argon purification systems are a valuable investment for anyone who relies on high-purity argon crystals. While the initial cost can be high, the long-term benefits of improved experimental accuracy, extended crystal lifespan, and reduced downtime outweigh the costs. We recommend choosing a system with multi-stage adsorption, cryogenic distillation, and real-time monitoring for optimal performance.

Insightful Q&A Section

Here are 10 frequently asked questions related to argon crystal decay and purification:

**Q1: What are the primary impurities that cause argon crystal decay?**

**A:** The primary impurities that contribute to argon crystal decay include oxygen, nitrogen, water vapor, hydrocarbons, and other noble gases. These impurities can disrupt the crystal lattice, accelerate decay, and compromise crystal performance.

**Q2: How does temperature affect the rate of argon crystal decay?**

**A:** Higher temperatures increase the rate of argon crystal decay by providing more energy for argon atoms to move within the crystal lattice and form defects. Maintaining a stable, low temperature is crucial for minimizing decay.

**Q3: What is the typical lifespan of an argon crystal in a particle physics experiment?**

**A:** The lifespan of an argon crystal in a particle physics experiment can vary depending on the purity of the argon, the operating temperature, and the level of radiation exposure. With proper purification and cooling, crystals can last for several years.

**Q4: Can argon crystal decay be reversed?**

**A:** In most cases, argon crystal decay is irreversible. Once the crystal lattice has been disrupted, it is difficult to restore it to its original state. Prevention is key.

**Q5: What are the key performance indicators (KPIs) for argon purification systems?**

**A:** Key performance indicators for argon purification systems include the output purity of the argon gas, the removal efficiency of various impurities, the flow rate of the system, and the energy consumption.

**Q6: How often should an argon purification system be maintained?**

**A:** The maintenance frequency of an argon purification system depends on the system’s design and operating conditions. Regular maintenance should include checking and replacing adsorbent materials, calibrating sensors, and inspecting for leaks.

**Q7: What is the role of activated carbon in argon purification systems?**

**A:** Activated carbon is used as an adsorbent material in argon purification systems to remove organic impurities, such as hydrocarbons, from the argon gas. Its high surface area allows it to effectively bind to these impurities.

**Q8: How does cryogenic distillation work in argon purification systems?**

**A:** Cryogenic distillation separates argon from other gases based on their boiling points at cryogenic temperatures. By carefully controlling the temperature, argon can be selectively condensed and separated from other gases.

**Q9: What are the safety considerations when operating an argon purification system?**

**A:** Safety considerations when operating an argon purification system include handling cryogenic fluids, working with high-pressure gases, and ensuring proper ventilation to prevent asphyxiation.

**Q10: What advancements are being made in argon purification technology?**

**A:** Advancements in argon purification technology include the development of more efficient adsorbent materials, the use of advanced sensors for real-time monitoring, and the integration of artificial intelligence for automated control and optimization.

Conclusion & Strategic Call to Action

In summary, understanding and mitigating argon crystal decay is crucial for ensuring the reliability and accuracy of various scientific and technological applications. Argon purification systems play a vital role in this process by removing impurities that can accelerate decay. By investing in a high-quality purification system and implementing proper maintenance procedures, researchers and engineers can significantly extend the lifespan of their argon crystals and improve the quality of their work. The future of argon crystal research hinges on continued advancements in purification and preservation techniques.

Share your experiences with argon crystal decay in the comments below. Explore our advanced guide to cryogenic technologies for further insights. Contact our experts for a consultation on argon purification solutions.