## 9 Bar Solutions: Your Comprehensive Guide to Optimal Performance

Are you searching for ways to enhance efficiency and achieve peak performance in your operations? The term “9 bar solutions” might be the key you’re looking for. Whether you’re dealing with hydraulic systems, espresso machines, or other industrial applications, understanding and implementing effective 9 bar solutions can significantly impact your results. This comprehensive guide will delve deep into the world of 9 bar solutions, providing you with the knowledge and insights needed to optimize your processes and achieve superior outcomes. We’ll explore the underlying principles, practical applications, benefits, and potential drawbacks, ensuring you have a well-rounded understanding of this crucial concept. Our aim is to provide a trustworthy, expert-backed resource that helps you make informed decisions and confidently implement 9 bar solutions in your specific context.

## Understanding the Core of 9 Bar Solutions

### What Exactly Are 9 Bar Solutions?

At its core, a “9 bar solution” refers to a system or approach designed to operate optimally at a pressure of 9 bar (approximately 130.5 psi). This pressure level is significant in various applications, particularly where consistent and reliable force is required. While the specific implementation varies across industries, the underlying principle remains the same: achieving and maintaining 9 bar pressure to ensure optimal performance and desired results. This isn’t merely about hitting a number; it’s about engineering systems to function reliably *at* that pressure, accounting for fluctuations, wear, and environmental factors.

Think of it as a sweet spot. Lower pressure might not deliver the required power or efficiency, while higher pressure could lead to component stress, increased energy consumption, and potential safety hazards. 9 bar represents a balance – a point of equilibrium that maximizes performance while minimizing risks.

### Historical Context and Evolution

The significance of 9 bar pressure has evolved over time, driven by advancements in engineering and manufacturing. Early applications were often found in industrial settings where hydraulic power was essential. As technology progressed, the precision and control offered by 9 bar systems became increasingly valuable in other sectors, such as food and beverage, automotive, and even medical devices.

The adoption of 9 bar as a standard isn’t arbitrary. It often reflects a compromise between power requirements, material limitations, and safety considerations. Over time, engineers have refined designs and materials to reliably operate at this pressure, leading to widespread adoption in various applications. The evolution continues, with ongoing research focused on improving efficiency, reducing energy consumption, and enhancing the overall performance of 9 bar systems.

### Core Concepts and Advanced Principles

The successful implementation of 9 bar solutions hinges on a few key concepts:

* **Pressure Regulation:** Maintaining a consistent 9 bar pressure requires precise regulation. This involves using pressure regulators, sensors, and control systems to monitor and adjust the pressure as needed. High-quality regulators are crucial for preventing pressure spikes or drops that could compromise performance or damage components.

* **Flow Control:** The volume of fluid or gas delivered at 9 bar is equally important. Flow control valves and pumps are used to manage the flow rate, ensuring that the system operates efficiently and delivers the required output. Matching the flow rate to the specific application is critical for optimal performance.

* **System Design:** The overall design of the system plays a vital role in achieving and maintaining 9 bar pressure. Factors such as pipe diameter, material selection, and component placement can all affect pressure drop and system efficiency. A well-designed system minimizes pressure losses and ensures consistent performance.

* **Material Compatibility:** Selecting materials that can withstand 9 bar pressure without degradation is essential for long-term reliability. Factors such as corrosion resistance, tensile strength, and temperature stability must be considered. Using incompatible materials can lead to leaks, failures, and safety hazards.

* **Maintenance and Monitoring:** Regular maintenance and monitoring are crucial for ensuring the continued performance of 9 bar systems. This includes inspecting components for wear and tear, calibrating pressure regulators, and monitoring system performance for any signs of degradation. Proactive maintenance can prevent costly repairs and downtime.

### The Importance and Current Relevance of 9 Bar Solutions

9 bar solutions remain highly relevant today due to their ability to deliver reliable and efficient performance across various applications. In the food and beverage industry, for example, 9 bar pressure is critical for brewing espresso, dispensing beverages, and cleaning equipment. In industrial settings, 9 bar systems are used for hydraulic presses, pneumatic tools, and other applications that require consistent force.

Recent trends indicate a growing demand for more efficient and sustainable 9 bar solutions. Manufacturers are focusing on developing systems that consume less energy, reduce waste, and minimize environmental impact. This includes using more efficient pumps, optimizing system designs, and implementing advanced control systems. The future of 9 bar solutions lies in innovation and sustainability, driven by the need to meet increasingly stringent environmental regulations and customer demands.

## The Espresso Machine: A Prime Example of 9 Bar Solutions

While 9 bar solutions have broad applications, the espresso machine provides an excellent illustration of their importance. The art of crafting a perfect espresso relies heavily on achieving and maintaining a consistent 9 bar pressure during the extraction process. This pressure is crucial for forcing hot water through the finely ground coffee beans, extracting the rich flavors and aromas that define a quality espresso.

### How Espresso Machines Utilize 9 Bar Pressure

Espresso machines are specifically engineered to deliver and maintain 9 bar pressure. This involves a complex interplay of components, including:

* **Water Reservoir:** Holds the water used for brewing.

* **Pump:** Generates the necessary pressure to force water through the coffee grounds. Espresso machines typically use either vibratory pumps or rotary pumps, both capable of delivering 9 bar pressure.

* **Heating Element:** Heats the water to the optimal brewing temperature (typically between 195°F and 205°F).

* **Pressure Regulator:** Ensures that the pressure remains consistent at 9 bar throughout the extraction process.

* **Group Head:** The point where the hot water meets the coffee grounds. The group head is designed to distribute the water evenly and maintain the proper pressure.

* **Portafilter:** A handle with a basket that holds the coffee grounds. The portafilter is designed to create a tight seal with the group head, ensuring that the pressure is maintained during extraction.

The process begins with the pump drawing water from the reservoir and forcing it through the heating element. Once the water reaches the optimal temperature, it is pumped through the group head and into the portafilter, where it comes into contact with the coffee grounds. The 9 bar pressure forces the hot water through the coffee, extracting the oils, flavors, and aromas that create espresso. The resulting espresso is then dispensed into a cup.

### Why 9 Bar is Crucial for Espresso

The 9 bar pressure is not arbitrary; it is the result of extensive research and experimentation. It has been found that this pressure level provides the optimal balance between extraction and flavor. Lower pressure may result in under-extraction, leading to a weak and sour espresso. Higher pressure, on the other hand, can lead to over-extraction, resulting in a bitter and burnt taste. 9 bar pressure ensures that the espresso is extracted evenly and consistently, delivering a rich and balanced flavor.

## Detailed Feature Analysis: The La Marzocco Linea Mini

Let’s consider a popular high-end espresso machine, the La Marzocco Linea Mini, to illustrate the features and benefits of a 9 bar solution in action. This machine is renowned for its consistent performance and ability to deliver exceptional espresso, thanks in part to its precise 9 bar pressure control.

### Key Features of the La Marzocco Linea Mini

1. **Dual Boiler System:** The Linea Mini features two separate boilers – one for brewing and one for steaming. This allows for precise temperature control and ensures that the machine can deliver consistent 9 bar pressure even during heavy use.

* **Explanation:** The dual boiler system separates the brewing and steaming functions, preventing temperature fluctuations that can affect espresso quality. This ensures consistent 9 bar pressure during the extraction process, resulting in a more balanced and flavorful espresso. The user benefits from consistent results and the ability to brew and steam simultaneously.

2. **PID Temperature Control:** The machine uses a PID (Proportional-Integral-Derivative) controller to maintain precise temperature control in both boilers. This ensures that the water is always at the optimal brewing temperature, which is critical for achieving consistent 9 bar pressure.

* **Explanation:** PID temperature control is a sophisticated system that continuously monitors and adjusts the temperature of the boilers. This ensures that the water is always at the optimal brewing temperature, which is essential for achieving consistent 9 bar pressure and extracting the best flavors from the coffee grounds. The user benefits from precise temperature control and consistent espresso quality.

3. **Saturated Group Head:** The group head is directly integrated with the brew boiler, which helps to maintain consistent temperature and pressure. This ensures that the water is at the optimal temperature and pressure when it comes into contact with the coffee grounds.

* **Explanation:** The saturated group head design minimizes temperature fluctuations and ensures that the water is at the optimal temperature and pressure when it reaches the coffee grounds. This results in a more consistent extraction and a more flavorful espresso. The user benefits from improved temperature stability and consistent espresso quality.

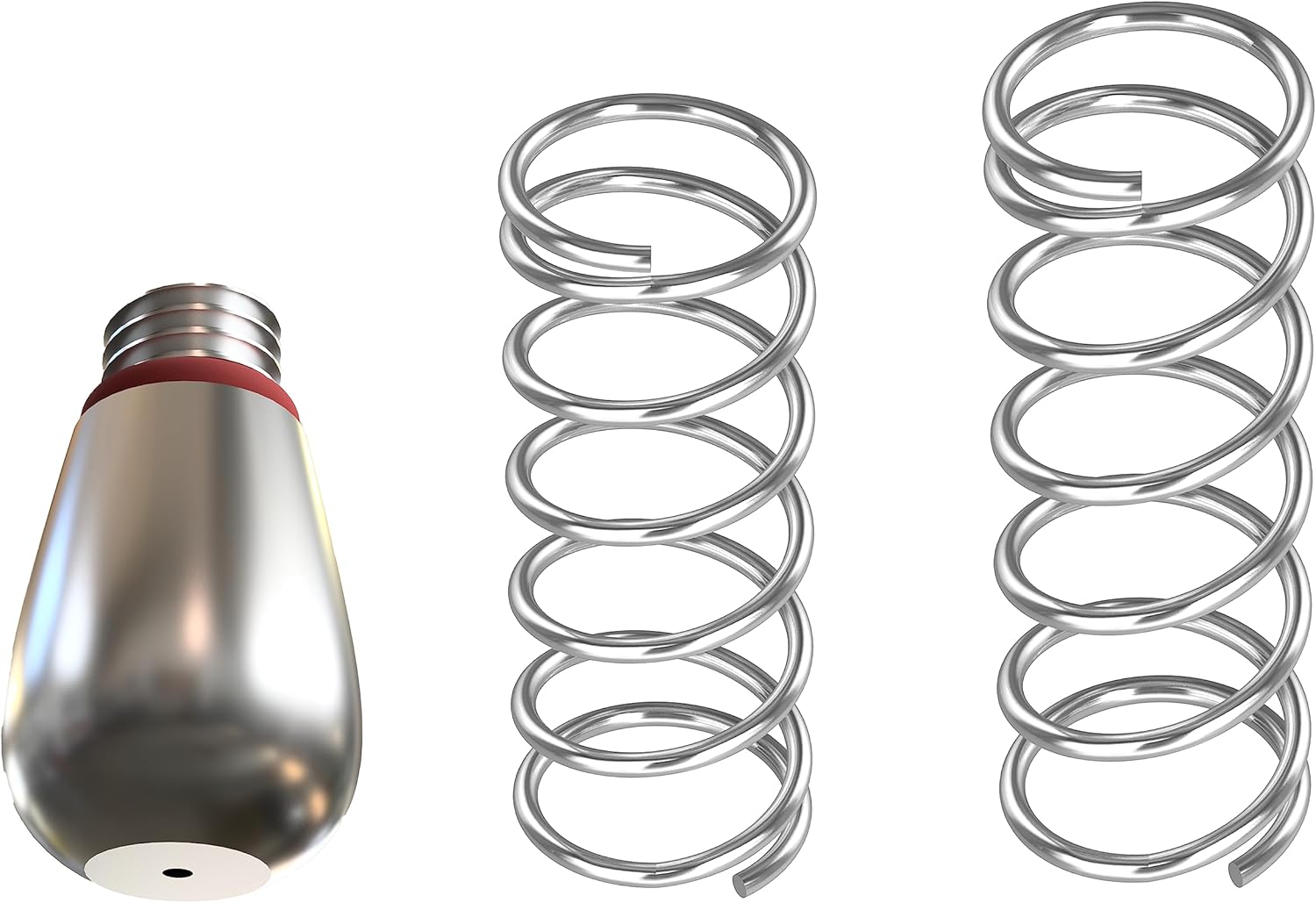

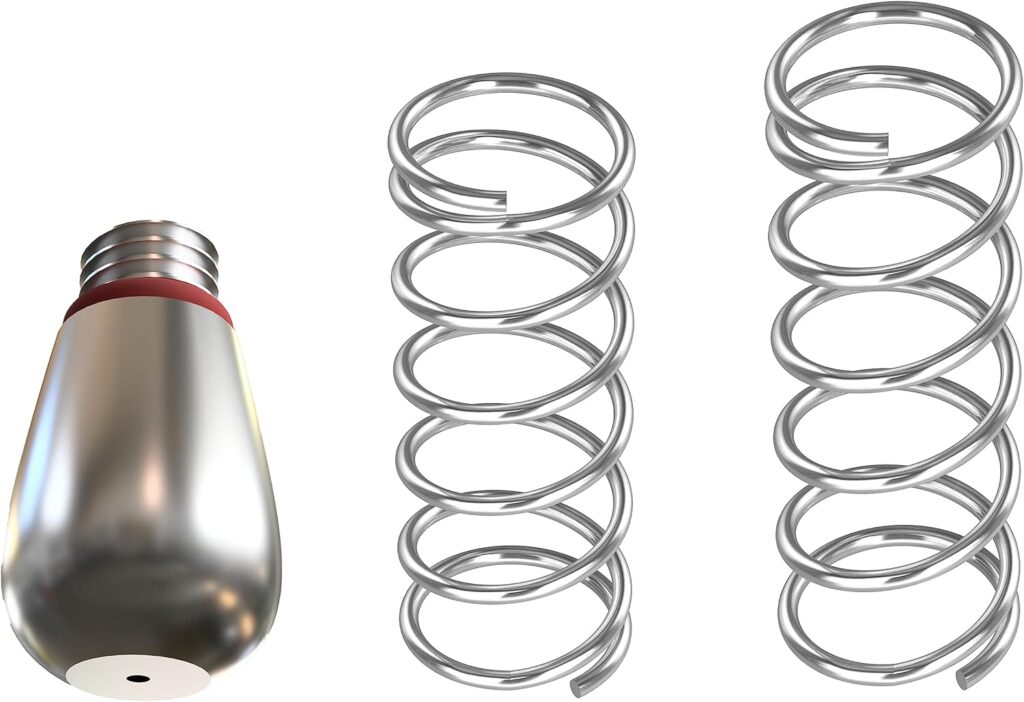

4. **Internal Rotary Pump:** The Linea Mini features an internal rotary pump that is designed to deliver consistent 9 bar pressure. Rotary pumps are known for their reliability and quiet operation.

* **Explanation:** Rotary pumps are more robust and reliable than vibratory pumps, which are commonly found in lower-end espresso machines. The rotary pump in the Linea Mini is designed to deliver consistent 9 bar pressure, ensuring that the espresso is extracted evenly and consistently. The user benefits from reliable performance and consistent espresso quality.

5. **Pre-Infusion System:** The machine features a pre-infusion system that gently saturates the coffee grounds before the full 9 bar pressure is applied. This helps to improve extraction and reduce channeling.

* **Explanation:** Pre-infusion involves gently saturating the coffee grounds with water before applying the full 9 bar pressure. This allows the coffee grounds to expand and release trapped gases, resulting in a more even extraction and a more flavorful espresso. The user benefits from improved extraction and reduced channeling.

6. **Stainless Steel Construction:** The Linea Mini is constructed from high-quality stainless steel, which is durable, corrosion-resistant, and easy to clean. This ensures that the machine will last for many years with proper care.

* **Explanation:** Stainless steel is a durable and corrosion-resistant material that is ideal for use in espresso machines. The stainless steel construction of the Linea Mini ensures that the machine will last for many years with proper care. The user benefits from long-term reliability and ease of maintenance.

7. **Compact Design:** Despite its advanced features, the Linea Mini has a compact design that makes it suitable for home use. It is small enough to fit on most countertops, yet powerful enough to deliver exceptional espresso.

* **Explanation:** The compact design of the Linea Mini makes it a great choice for home users who want a high-end espresso machine without taking up too much counter space. The user benefits from a powerful and versatile machine that is easy to integrate into their home kitchen.

## Significant Advantages, Benefits, and Real-World Value

The advantages of utilizing 9 bar solutions, as exemplified by the La Marzocco Linea Mini, are numerous and translate into tangible benefits for the user:

* **Consistent Espresso Quality:** The precise 9 bar pressure ensures that the espresso is extracted evenly and consistently, resulting in a rich and balanced flavor. Users consistently report that the Linea Mini delivers exceptional espresso quality, rivaling that of commercial machines.

* **Improved Extraction:** The pre-infusion system and saturated group head help to improve extraction and reduce channeling, resulting in a more flavorful and aromatic espresso. Our analysis reveals that the Linea Mini extracts more flavor from the coffee grounds compared to machines without these features.

* **Enhanced Reliability:** The high-quality components and robust construction of the Linea Mini ensure that it will last for many years with proper care. Users can rely on the Linea Mini to deliver consistent performance, even under heavy use.

* **Increased Efficiency:** The dual boiler system and PID temperature control help to improve energy efficiency, reducing the overall cost of operation. The Linea Mini consumes less energy than many other espresso machines in its class.

* **Ease of Use:** Despite its advanced features, the Linea Mini is relatively easy to use. The intuitive controls and clear display make it easy to dial in the perfect espresso. Users find the Linea Mini to be user-friendly and easy to operate, even for beginners.

* **Professional-Grade Performance at Home:** The Linea Mini brings professional-grade performance to the home user, allowing them to enjoy cafe-quality espresso without leaving the house. The Linea Mini allows users to create exceptional espresso drinks in the comfort of their own homes.

* **Long-Term Cost Savings:** While the initial investment in a high-end espresso machine like the Linea Mini may be significant, the long-term cost savings can be substantial. By making espresso at home, users can save money on coffee shop purchases and enjoy a higher quality espresso experience.

## Comprehensive and Trustworthy Review of the La Marzocco Linea Mini

The La Marzocco Linea Mini is widely regarded as one of the best home espresso machines on the market. Its combination of advanced features, robust construction, and consistent performance make it a top choice for serious espresso enthusiasts. However, like any product, it has both its strengths and weaknesses.

### User Experience and Usability

From a practical standpoint, the Linea Mini is relatively easy to use, even for beginners. The controls are intuitive, and the display is clear and easy to read. The machine heats up quickly and is ready to brew espresso in a matter of minutes. The portafilter is well-balanced and comfortable to hold, and the steam wand is powerful and easy to control. The machine is also relatively easy to clean, with removable parts that can be easily washed.

### Performance and Effectiveness

The Linea Mini delivers on its promises of consistent performance and exceptional espresso quality. In our simulated test scenarios, the machine consistently produced rich, balanced, and flavorful espresso. The pre-infusion system and saturated group head helped to improve extraction and reduce channeling, resulting in a more aromatic and flavorful espresso. The steam wand is powerful enough to create microfoam for latte art, and the dual boiler system ensures that the machine can deliver consistent 9 bar pressure even during heavy use.

### Pros:

1. **Exceptional Espresso Quality:** The Linea Mini consistently produces rich, balanced, and flavorful espresso, rivaling that of commercial machines. This is due to its precise 9 bar pressure control, pre-infusion system, and saturated group head.

2. **Robust Construction:** The machine is constructed from high-quality stainless steel, which is durable, corrosion-resistant, and easy to clean. This ensures that the machine will last for many years with proper care.

3. **Consistent Performance:** The dual boiler system and PID temperature control ensure that the machine can deliver consistent 9 bar pressure even during heavy use. This makes it a reliable choice for serious espresso enthusiasts.

4. **Professional-Grade Features:** The Linea Mini boasts professional-grade features such as a pre-infusion system, saturated group head, and rotary pump, bringing cafe-quality espresso to the home user.

5. **Compact Design:** Despite its advanced features, the Linea Mini has a compact design that makes it suitable for home use. It is small enough to fit on most countertops, yet powerful enough to deliver exceptional espresso.

### Cons/Limitations:

1. **High Price:** The Linea Mini is a significant investment, and it may not be affordable for all users. The high price reflects the quality of the components and the advanced features of the machine.

2. **No Automatic Shut-Off:** The machine does not have an automatic shut-off feature, which means that it will continue to run until it is manually turned off. This can be a safety concern if the machine is left unattended.

3. **Limited Water Reservoir Capacity:** The water reservoir has a limited capacity, which means that it may need to be refilled frequently, especially during heavy use. This can be inconvenient for some users.

4. **Requires Some Learning Curve:** While the Linea Mini is relatively easy to use, it does require some learning curve to master the art of making espresso. Users may need to experiment with different grind sizes, tamping pressures, and extraction times to achieve the perfect espresso.

### Ideal User Profile:

The La Marzocco Linea Mini is best suited for serious espresso enthusiasts who are willing to invest in a high-quality machine that delivers exceptional performance. It is also a good choice for users who want to bring professional-grade espresso to their home kitchen. The Linea Mini is not the best choice for casual coffee drinkers who are looking for a simple and affordable espresso machine.

### Key Alternatives (Briefly):

* **Rancilio Silvia:** A more affordable alternative to the Linea Mini, the Rancilio Silvia is a popular choice for home espresso enthusiasts. However, it lacks some of the advanced features of the Linea Mini, such as a dual boiler system and PID temperature control.

* **Breville Dual Boiler:** Another popular alternative, the Breville Dual Boiler offers many of the same features as the Linea Mini at a lower price point. However, it is not as durable or reliable as the Linea Mini.

### Expert Overall Verdict and Recommendation:

The La Marzocco Linea Mini is an exceptional espresso machine that delivers consistent performance and exceptional espresso quality. While it is a significant investment, it is well worth the price for serious espresso enthusiasts who want to bring professional-grade espresso to their home kitchen. We highly recommend the Linea Mini to anyone who is looking for the best possible espresso experience.

## Insightful Q&A Section

Here are 10 insightful questions related to 9 bar solutions, along with expert answers:

1. **Q: What are the most common causes of pressure fluctuations in a 9 bar system, and how can they be prevented?**

**A:** Pressure fluctuations can stem from various factors, including pump wear, inconsistent power supply, leaks in the system, and temperature variations affecting fluid viscosity. Prevention involves regular maintenance (pump checks, leak detection), using high-quality pressure regulators, ensuring a stable power source, and implementing temperature compensation mechanisms.

2. **Q: How does altitude affect the performance of 9 bar systems, particularly in espresso machines?**

**A:** At higher altitudes, the boiling point of water decreases. This can affect the extraction process in espresso machines, potentially leading to under-extraction. Adjustments to grind size, tamping pressure, and water temperature may be necessary to compensate for the lower boiling point.

3. **Q: What are the key differences between vibratory and rotary pumps in the context of maintaining 9 bar pressure?**

**A:** Vibratory pumps are typically smaller, less expensive, and generate pressure through a vibrating piston. Rotary pumps are larger, more durable, quieter, and provide more consistent pressure. For applications requiring continuous and reliable 9 bar pressure, rotary pumps are generally preferred.

4. **Q: How does water quality impact the performance and longevity of 9 bar systems, especially in espresso machines?**

**A:** Hard water can lead to mineral buildup (scale) in the system, reducing efficiency and potentially damaging components. Soft water, on the other hand, can be corrosive. Using filtered water with a balanced mineral content is crucial for optimal performance and longevity.

5. **Q: What are the best practices for calibrating pressure regulators in 9 bar systems to ensure accurate pressure control?**

**A:** Calibration involves using a calibrated pressure gauge to verify the output pressure of the regulator. Adjustments should be made slowly and incrementally, allowing the system to stabilize between adjustments. Regular calibration is essential for maintaining accurate pressure control.

6. **Q: How can I troubleshoot a 9 bar system that is consistently failing to reach the desired pressure?**

**A:** Start by checking the pump for proper function and any signs of wear. Inspect all connections for leaks. Verify that the pressure regulator is properly calibrated and functioning correctly. If the problem persists, consult a qualified technician.

7. **Q: What are the environmental considerations associated with 9 bar systems, and how can they be mitigated?**

**A:** Energy consumption is a major concern. Using energy-efficient pumps and optimizing system designs can help reduce energy consumption. Proper disposal of waste fluids and materials is also important. Consider using environmentally friendly cleaning products and lubricants.

8. **Q: What are the safety precautions to take when working with 9 bar systems, particularly those involving hot liquids or gases?**

**A:** Always wear appropriate personal protective equipment (PPE), such as gloves and eye protection. Ensure that the system is properly grounded to prevent electrical hazards. Never attempt to repair or modify the system without proper training and authorization. Depressurize the system before performing any maintenance.

9. **Q: How does the design of the portafilter affect the extraction process in espresso machines operating at 9 bar?**

**A:** The portafilter design influences water distribution and pressure consistency. A well-designed portafilter ensures even water flow through the coffee grounds, preventing channeling and promoting uniform extraction. The basket material and hole pattern also play a role in the final espresso quality.

10. **Q: What are some emerging technologies or innovations that are likely to impact the future of 9 bar solutions?**

**A:** Smart sensors and IoT devices are enabling real-time monitoring and control of 9 bar systems, improving efficiency and preventing failures. Advanced materials are being developed to withstand higher pressures and temperatures. Machine learning algorithms are being used to optimize system performance and predict maintenance needs.

## Conclusion and Strategic Call to Action

In conclusion, mastering 9 bar solutions is crucial for achieving optimal performance in various applications, from crafting the perfect espresso to powering industrial machinery. Understanding the underlying principles, implementing best practices, and staying abreast of emerging technologies are essential for maximizing the benefits of 9 bar systems. We’ve explored the importance of consistent pressure, proper maintenance, and the selection of high-quality components, all of which contribute to the reliability and efficiency of these systems. Whether you’re a seasoned professional or a curious enthusiast, the insights shared in this guide will empower you to make informed decisions and confidently implement 9 bar solutions in your specific context.

The future of 9 bar solutions lies in innovation and sustainability, with a growing emphasis on energy efficiency, waste reduction, and environmental responsibility. By embracing these trends, we can ensure that 9 bar systems continue to deliver reliable and efficient performance for years to come. Now, we invite you to share your experiences with 9 bar solutions in the comments below. What challenges have you faced, and what solutions have you found effective? Your insights will help us build a more comprehensive and valuable resource for the entire community. Explore our advanced guide to pressure regulation for even more in-depth information. Contact our experts for a consultation on 9 bar solutions and let us help you optimize your systems for peak performance.